January brought no shortage of safety surprises. As our engineers carried out LOLER inspections across sites, several serious equipment defects were uncovered — many of which could have led to dangerous failures. Take a look at some of the key issues we found this winter, and why regular inspections are critical during colder months.

This pallet truck had a steer wheel missing.

Some excessive wear on hydraulic hoses on a MEWP.

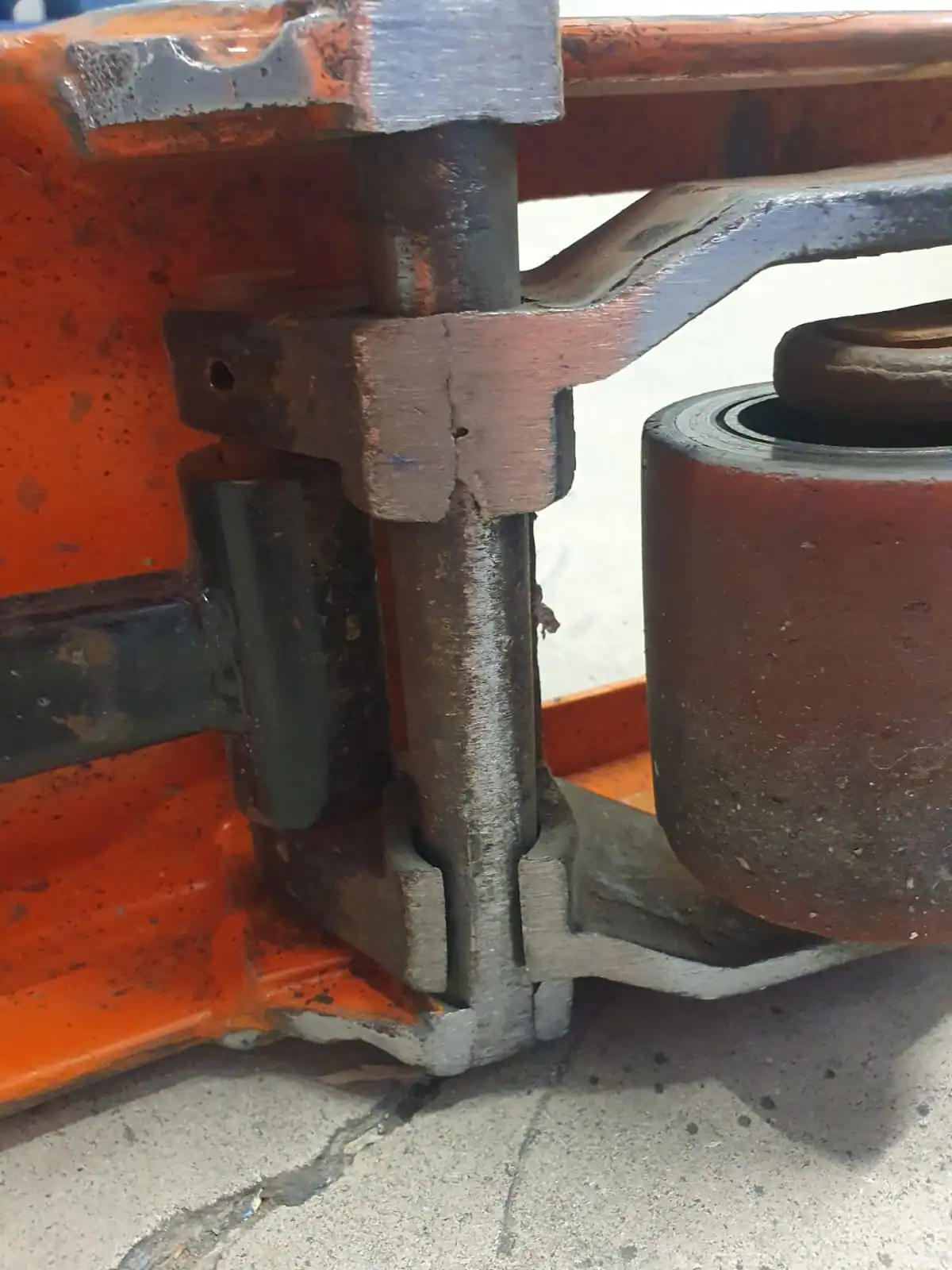

Collapsed bearing resulting in wear of load wheel assembly on a pallet truck.

Some excessive tear on this sling.

Why invest in equipment inspections?

It’s very easy to question the value of good health and safety practices in the workplace. As a business owner, when you invest in a new piece of machinery it increases output, efficiency and the overall bottom line.

Where is the return when you invest in good safety management?

Or better still, where is the value in investing in regular equipment inspections (aside from meeting your legal obligations of course)?

- Maybe you might be happy sending a staff member 10 metres up in the air in this MEWP basket, or

- Maybe you might sleep soundly without knowing the condition of your lifting equipment, or

- Maybe you don’t want to get an idea of the state of equipment within your business.

For the conscientious employer or business manager looking to…

✅ Meet their legal obligations as per LOLER and GA legislation.

✅ Protect workers enabling them to return home safely.

✅ Reduce absences ensuring more efficient and productive workspaces.

…there is a team at Dynamic Safety Solutions.

Contact us now to book your LOLER inspection or GA1 inspection today.